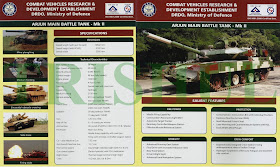

Contrary to widespread speculation, the Indian

Army (IA) has not forsaken or given up on the Arjun Mk.2 main battle tank

(MBT). Instead, for the past four years, the IA’s Directorate General of

Mechanised Warfare has been overseeing a collective developmental effort

involving the DRDO, and the MoD-owned defence public-sector undertakings and

private-sector OEMs that will in the near future result in a fully-loaded 60-tonne MBT armed

with a 120mm smoothbore cannon while retaining the existing 1,400hp powerpack.

Under the supervision and guidance of the DRDO’s

Avadi-based Combat Vehicles Research & Development Establishment (CVRDE),

and with the help of the MoD’s Directorate General of Quality Assurance (DGQA)

and the IA’s Corps of Electronics & Mechanical Engineers (EME), a number of

key decisions have been to achieve a weight reduction of 8 tonnes in the

existing design of the 68-tonne Arjun Mk.1A MBTs, 118 of which are now in

delivery.

For starters, the baseline hull of the Arjun Mk.2 will no longer be

built with imported low-carbon, nickel-chromium-molybdenum rolled

homogeneous armor (RHA) steel, but with lighter high-nitrogen steel (HNS) whose production technology has been

mastered by the DRDO’s Hyderabad-based Defence Metallurgical Research Laboratory (DMRL) and has been transferred to Jindal Stainless Steel Ltd (Hisar). HNS will also be

used by TATA Motors Ltd for producing the 83 Kestrel 8 x 8 armoured personnel

carriers already on order.

HNS is produced in a four-step process: primary

melting of the steel can carried out in either induction furnace or electric

arc furnace by using appropriate raw materials; secondary melting can be

carryout in by nitrogen gas-purging in to the metal; under ladle refining,

ferro-nitrates are added to molten metal for obtaining final nitrogen content

in the alloy if it is required and hot-rolling is carried out in a single heat,

without reheating. Minimum percentage of reduction should not be less than 75%

of the slab thickness. To be placed in strategic locations in both the hull and

turret will be the DRDO-developed ‘Kanchan’ ceramics-based composite laminate armour tiles

as well as indigenously-built explosive reactive armour (ERA) tiles developed

by the DRDO’s High

Energy Materials Research Laboratory (HEMRL) on the front and sides of the hull and turret sections.

To ensure optimal weight budgeting during the

production engineering stage, the CVRDE has contracted Dynamatic Technologies Ltd,

which specialises in complex,

five-axis robotic machining, as well as in converting two-dimension paper

blueprints into three-dimension computer model that are more precise, and have

tighter tolerances. Digitising the drawings creates a baseline configuration

for greater accuracy. This in turn streamlines manufacturing, since conventional manufacturing

based on two-dimensional paper blueprints tend to leave tiny gaps between the

different components of an assembly that were filled with shims, leading to increased weight. But by digitising blueprints, those tiny gaps can be

entirely eliminated during the manufacturing process.

Under another weight-reduction exercise, the

CVRDE has contracted the Alicon Group for building all-aluminium road-wheels

and ventilators for not only the Arjun Mk.2, but also for the IA’s existing upgraded

T-72CIA medium tanks. They will replace the all-steel road-wheels built by Sundaram

Industries for the Arjun

Mk.1A. Similarly, TATA Power SED has been contracted for producing all-electric

turret stabilisation/traverse systems, in place of the existing

electro-hydraulic system.

Improvements have also been made to the 1,400hp powerpack (comprising the

MTU

838 Ka-501 diesel engine and RENK’s RK-304S gearbox) through the usage of

indigenously developed cooling systems.

However, the area that will see the Arjun Mk.2 emerging as a true new-generation

MBT will be vectronics, and in particular the battlespace management system

(BMS), which has been designed

to operate at the unit-level and below, and which will synthesise the battlespace

situational awareness picture for the unit commander, whether it be a

mechanised infantry regiment or an armoured regiment. The MBT and selected

infantrymen will thus become situational awareness platforms.

This project,

which was started only in 2008, has since been pushed at a faster rate as this

constitutes the cutting edge of the IA’s theatre-level Command Information Decision

Support System (CIDSS) programme that is being run by IA HQ’s Directorate of

Information Systems. The Future Infantry Soldier as a System (F-INSAS), which

is also a part of the CIDSS project, is being progressed by the IA HQ’s

Directorate of Infantry but will be a part of the overall BMS and battlespace

surveillance system (BSS) network of the IA.

The BSS and BMS are in turn being

integrated by IA HQ’s Directorate of Signals with other components of the fourth-generation

Tactical Command, Control, Communications and Information (TAC-C3I) system

through the CIDSS channel. Through the BMS and BSS the IA wants to provide a Divisional-level

command-and-control system spanning the entire tactical battle area (TBA)

spreading across individuals, detachments, combat platforms, sensors, sub-units,

units to the Brigade Commander/Regimental Commander; achieve faster reaction

capability and flexibility in command and control by providing information

automatically in the right place at the right time, thereby compressing the

OODA loop; provide a strong foundation for making decisions based on near-real

time situational awareness and battlespace transparency, providing consistent

and well-structured information, thereby enhancing the information handling

capability of commanders at all levels; and strengthening information exchange

by having a strong messaging and replication mechanism.

The BMS will be a highly mobile and integrated

system with high data transmission rates, comprising a tactical hand-held computer

with individual soldiers, tactical computers at Battle Group HQ, and armoured vehicles

employing application/database servers connected via a data-enabled TAC-C3I communications

network, all of which generate a common operational picture of the TBA. The software-defined

radio-based communications nets will optimally utilise the bandwidth available

for military communications, and will not interfere with the legacy

communications hardware. They will be fitted to MBTs, ICVs and APCs and will be

scalable to ensure their availability to all elements ranging from man-portable

SDRs to high-power SDRs for armoured vehicles.

The original proposed time-lines for

implementation of the BMS and BSS were as follows:

Phase-1: Integration of

the system, establishment of the testbed lab and field-trials at testbed

locations (one Combat Group and three Infantry Battalion Groups) by 2012.

However, this timeline was subsequently stalled for two years due to indecision

in the delimitation between the BMS and the F-INSAS.

Phase-2: Equipping of all

armoured and mechanised infantry formations commencing in 2017.

Phase-3: Upgradation of

the system by 2022.

Both the BMS and

F-INSAS will make use of a host of digitised GIS-based tools (pertaining to

both friendly and enemy territories) that are now available (work on them began

in 2009) for the IA’s South-Western, Western and Northern Command HQs and that can

be readily uploaded on to any armoured vehicle’s autonomous land navigation

system (ALNS) and BMS terminal. Military

Geospatial Information System (MGIS) helps in generating terrain

trafficability maps, commonly referred to as Going Maps (GM), when data

pertaining to five thematic layers, viz., soil, slope, moisture, land use, and

landform is fed into the system. It is then integrated to produce the GMs in a

three-level hierarchical manner. Terrain

Feature Extraction System (TFES) is used for extracting terrain parameters

or themes (land-use/land cover, landform, and soil type) from satellite images

and associated knowledge base in an automated mode. The land use, landform, and

soil layer has 10, 28, and 12 classifications, respectively. For land-use

classification, a multi-layer perceptron (MLP) is used for training and

subsequent generation of corresponding themes. The landform classification uses

a texture-based method for creating a database that is used for training MLP. Terrain Reasoner System (TRS) helps

decision-makers (troop commanders, wargamers and mission planners) in a combat

development setting for arriving at route alternatives that are largely

determined by the threat capability of the obstacles and strategic nature of

the regions to be negotiated for a pre-specified mission accomplishment risk

factor (MARF). The problem of navigation and route planning of vehicles or

troops is defined as the final behavioural outcome of a sequence of complex

decisions involving several criteria that are often conflicting and difficult

to model. A fuzzy inference system has been built to implement the

perceive-reason-act decision cycle of a moving agent representing a vehicle or

a foot soldier in a safety-critical tactically driven scenario. Terrain Matching System (TMS) is an

intelligent decision-support system based on the integration of CBR and fuzzy

multi-criteria decision-making.

The F-INSAS

project will be implemented in three phases—Phase-1 includes weapons, body

armour, clothing and individual equipment; Phase-2 is the target acquisition

system and Phase-3 comprises the computer sub-system, SDR sub-system, and

operating software integration. Since the Directorate of Infantry has been developing

Phase-3 of F-INSAS on its own, rather than being part of the BMS project, this

has amounted to re-inventing the wheel. Instead, what should have been done was

to develop Phase-3 of F-INSAS as part of the overall BMS developmental effort.